In line with the increase in the number of wire harness circuits used, reecting the growing presence of electronic technologies in automobiles, we have reduced wire sizes and weight, bolstered productivity and incorporated environmental considerations and recycling.

Utilizing on the materials technologies of the Furukawa Electric Group on metallic materials, plating, etc., we have reduced the size and improved reliability.

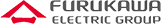

The lighter weight of cars is a key factor for fuel economy and safety performance. The weight of a wire harness is in the region of 20 to 50 kilograms per car. Lightening the weight of a car is an essential factor in improving fuel economy and extending the driving range of electric vehicles. The wire harness weight is an important factor in overall performance. By switching from copper to aluminum wiring, we have been able to reduce the weight by 10 to 40%

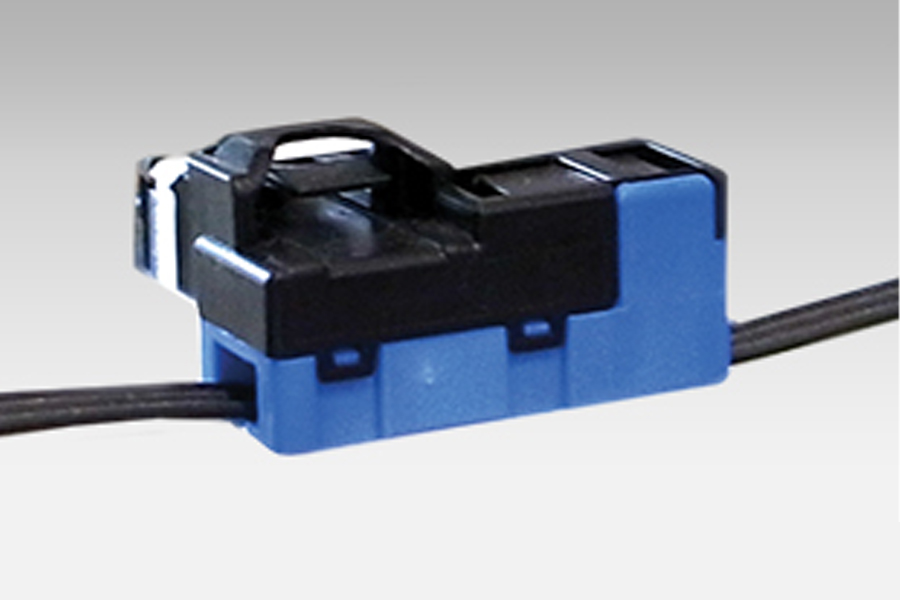

BUS harnesses are harnesses made by pressure welding multiple PCB built in connectors (smart connectors) to 3-circuit ribbon wire. Furukawa Electric Group has realized reductions in wiring and weight by suppressing the number of servo motors that move doors for air outlet switching or inside air / outside air switching, etc., in air conditioners using smart connectors based on multiplex communication.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |